Jinan Apollo Wood Plastic Composite material Co.,Ltd is one of the professional manufacturers of Wood Plastic Composite (WPC) profiles. We specialize in wpc profiles that could be applicated to wall cladding , outdoor decking , outdoor wall panel, flower pot , gallery, handrail or fencing,garden chair, rubbish bin etc. Now there are 20 products lines waiting for your orders . Our new workshop have b

Contact Now

WPC outdoor decking is much welcome materials city construction and ourdoor profiles. We specialize at producing WPC in a best wish of saving you all kinds of cost. Because we believe it is reliable: anti-slip, ati-oxidation, minimal moisture absorption, resistant to insects, etc. You can enjoy years of low maintenance service in such good landscape.

Contact Now

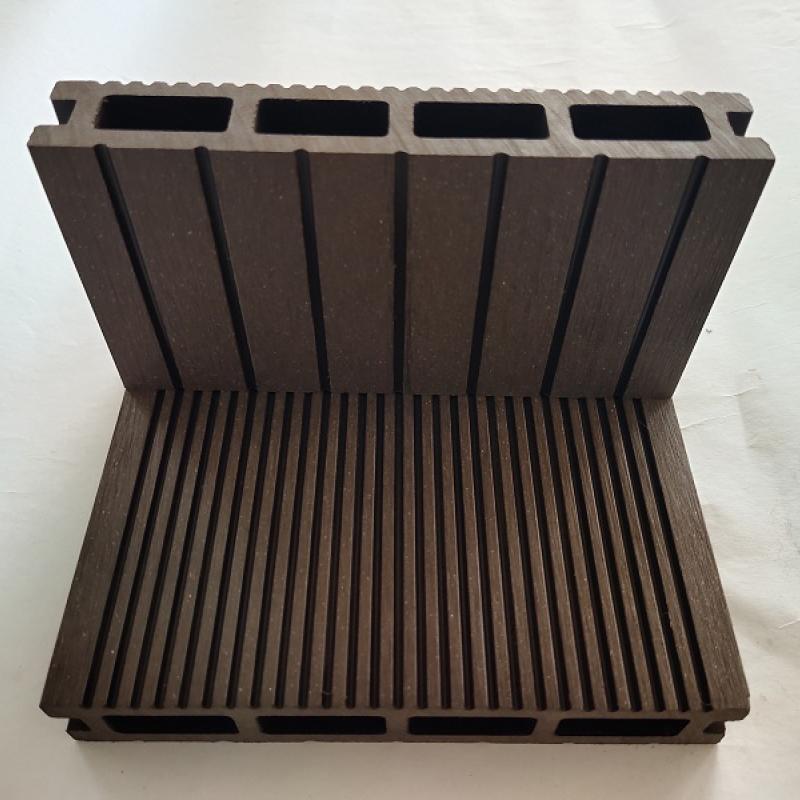

IntruductionCo-extruded wpc decking ground is crafted from recyclable wooden flour, hdpe and first rate components. in assessment with the wpc robust decking, the hollow one is lighter and hundreds a whole lot masses a great deal a good deal less pricey. moreover it could present the simplest of a type sun sun sun sunglasses and the amazing style. the installation can be speedy and clean. it’s complete call is wooden plastic composite decking(wpc decking). and it performs with its top notch water resistance, mainly appropriate for use in a moist environment.

Contact Now

Wood Plastic Composite (WPC) is a new eco-friendly composite material. Because of the multiple advantages,it is economic and practical.

Contact Now

The better decorative choice for a villa or a house, beside wooden material, WPC materials may be the mordern feeling and fast and easy one. It requires no maintenance or the easy cleaning as your feelings and can be installed using small and simple accessories. And this installation process is also fun work.

Contact Now

IntruductionSolid Floor Decking is crafted from recyclable wooden flour, HDPE and different additives. Compared with the WPC strong decking, the hollow one is lighter and cheaper. Also it can gift the specific colorations and the specific style. The installation can be speedy and easy. It’s entire call is Wood plastic composite decking(WPC Decking). And it plays with its top notch water resistance, particularly appropriate to be used in a damp environment.

Contact Now

IntruductionStable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings.

Contact Now

IntruductionStable floor decking is made from recyclable wood flour, hdpe and distinctive components. in comparison with the wpc strong decking, the hollow one is lighter and cheaper. also it could gift the particular colours and the specific fashion. the set up may be rapid and easy. it’s entire call is timber plastic composite decking(wpc decking). and it performs with its notable water resistance, specially suitable to be used in a moist surroundings.

Contact Now

Features of wpc products:1. Eco-friendly made from recycled plastics and non-virgin wood.100% recyclable, eco-friendly, saving forest resources2. Highly termite resistant,good look of the natural wood ,but no timber problems3. Timber like surface treatment for an excellent non-slip feel.4. No staining or painting required, no cracking, no warping,anti-slip5. Water and corrosion resistant, alkali-proof, moth-proof, stainable and malleable, low pollution risk and odor-free6.Available in different colors

Contact Now

IntruductionThe software model is used for manufacturing bushes, pools, flower bins, entertainment included benches in inexperienced areas and squares, or even may be matched with different profiles to shape simple and heavy fences in keeping with the scene.SpceificationBasic DescriptionNameWood-plastic floorSerial NumberAPL—140*25MaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecification140*25(mm)ColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC Deck

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental

Contact Now

Basic DescriptionNameWood-plastic floorSerial NumberVariousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3918909000Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental

Contact Now

Basic DescriptionNameWood-plastic Composite FenceSerial NumberVaviousMaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecificationVariousColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollowApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Southeast Asia,Central Asia,Europe & North AmericaHS Code3926909090Lead Time:15 Days for 1X20 GP ContainerTransport Package:Pallet ,Stretch Film,fluting paper (for whole container)AdvantagesWear-resistingWater-proofDam-proofFireproofNo-pollutionEnvironmental

Contact Now

Details:Length could be customised. Our suggestion is within 3 metres, like 2.2 m, 2.4 m or 2.9 m. Becasuse in this level of the lengths, the profiles could be more easily packaged, to protect the goods during the transportation.We also could supply all accessories in need of the installing the decking boards. Also we could supply installation instructions and successful installation video. We could make our products meet your DIY request.

Contact Now

Easy installation. Our technology department could provide you the installation instruction and the real engineering project video when you require.It is very easy and it could save labor cost.WPC product could be cut, nailed, drill, screw with normal woodworking tools. This kind product is water-proof, fire-resistant, anti-corrosion, insect-prevention... And this kind handrail performance is better than the normal wood.

Contact Now

IntruductionThe utility model is used for manufacturing trees, pools, flower boxes, leisure integrated benches in green spaces and squares, and even can be matched with other profiles to form simple and heavy fences according to the scene.SpceificationBasic DescriptionNameWood-plastic floorSerial NumberAPL—140*25MaterialWood,HDPE,Some other AdditiveComponent:60% Wood+ 30% HDPE+ 10% AdditivesSpecification140*25(mm)ColorTeak,Light Grey,Coffee,Chocolate,BlackCertificateCE,SGS,ISOClassificationHollow and SolidApplication:Outdoor,Customized:Non-CustomizedMOQ:200 Sq m for WPC DeckingMain Market:Sout

Contact Now